|

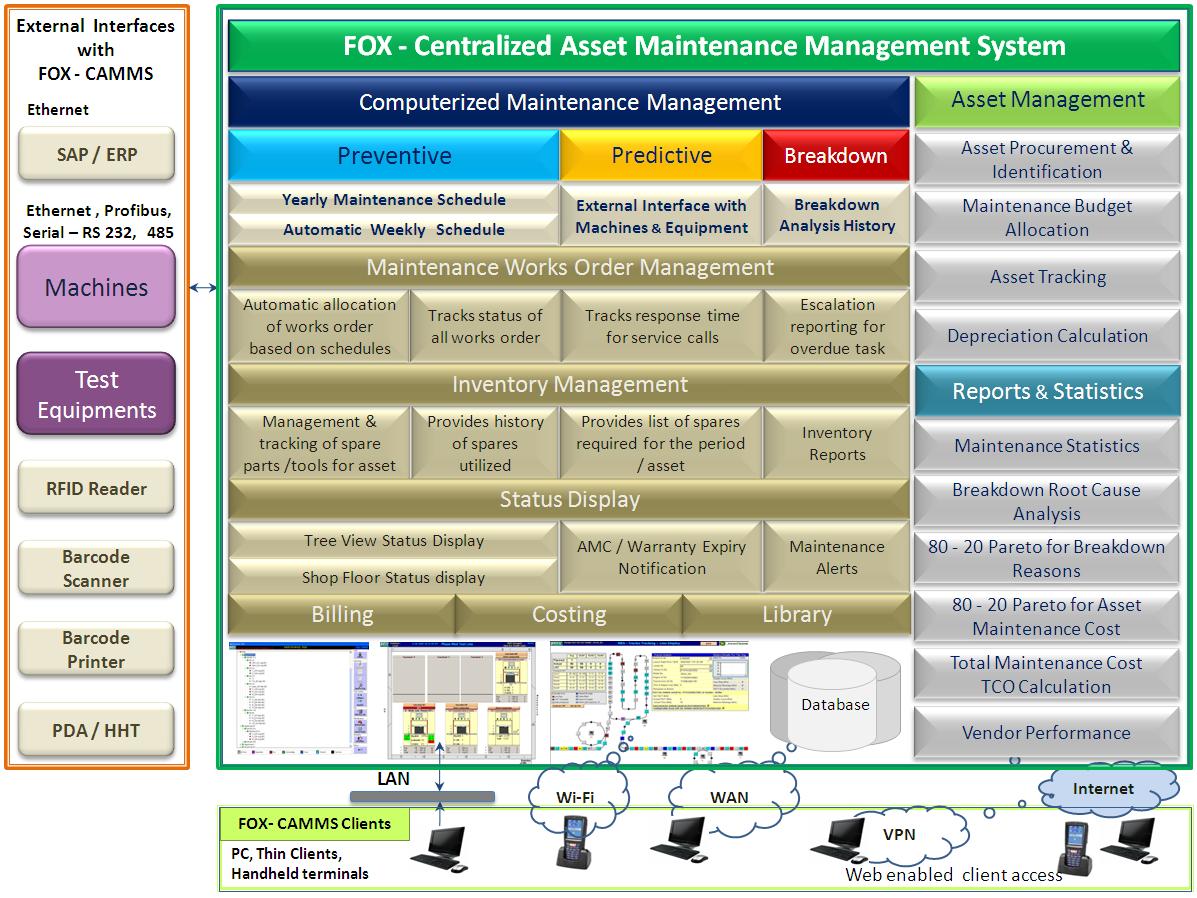

| Software architecture of FOX CAMMS with its external interface |

| FOX-CAMMS is a configurable, multi-location, multi-user web application that ensures easy operation of : |

| |

Asset management |

| |

|

- budget allocation for the assets, procurement, tracking, upgradation, restoring asset into the system after repair, disposal, depreciation calculation, total cost of ownership (TCO) calculation, etc |

| |

Maintenance management |

| |

|

- scheduling preventive maintenance tasks, automatic work order generation for the maintenance tasks based on schedule or service call generation, automatic allocation of tasks, tracking the status of maintenance tasks, calculate cost incurred on maintenance, root cause analysis for breakdown, etc |

| |

Inventory management |

| |

|

- automatic request generation for the material based on availability of assets, its spare parts or tools, their delivery and lead time, criticality, tracking of inventory cost, history of spares utilized, etc |

| |

Service desk functionalities |

| |

|

- generating the service call tickets, tracking its status, tracking the time to acknowledge and restore the service. |

| FOX-CAMMS is used to manage maintenance of various types of assets, viz, |

| |

General assets |

| |

|

It is used to manage and track buildings, structures, machines and equipments like boilers, pumps, motors, lighting components and other than those used for IT. |

| |

IT assets |

| |

|

IT assets are further divided as software assets and hardware assets. |

| |

|

IT Software assets -Management of IT software assets for optimum usage throughout all stages of its lifecycle. |

| |

|

IT Hardware assets -Management of IT hardware components like computers, computer networks, telecom networks, etc |

| FOX-CAMMS may have an external interface with |

| |

SAP / ERP |

| |

|

The information required for budget allocation, PO generation, maintenance work order generation, human resource and skill matrix, billing and invoice can come from external interface of SAP / ERP or alternatively can be managed in FOX-CAMMS. |

| |

Machines |

| |

|

To get machine running hours, machine downtime or to get online parameters of the machine using OPC or any other protocol over Ethernet / serial bus interface. Any test equipment like machines, PLCs, etc |

| |

RFID readers,barcode scanners , wireless handheld terminals or thin clients can be used to track |

| |

|

- asset / inventory |

| |

|

- response time taken to acknowledge and restore a service |

| |

|

- to display the maintenance status of assets (running, stop, under maintenance, maintenance activities pending/ closed / due/ future scheduled, etc) |

| |

|

- to display the status of all works order number |

| FOX-CAMMS modules are : |

| |

|

- Asset Procurement |

| |

|

- Asset Budget Allocation |

| |

|

- Asset Tracking , |

| |

|

- Asset Maintenance Management |

| |

|

- Inventory Control |

| |

|

- Reports & Statistics |

| FOX-CAMMS modules details : |

| |

Asset Budget Allocation : |

| |

|

|

- Allocation of budget for different cost centers for the financial year. |

| |

|

|

- Allocation of budget for maintenance of assets. |

| |

Asset Procurement : |

| |

|

|

- Initiate procurement from purchase request. |

| |

|

|

- Asset identification through unique barcode, RFID tag or system generated unique ID |

| |

Asset Tracking : |

| |

|

|

- Asset allocation |

| |

|

|

- Asset movement |

| |

|

|

- Asset Up gradation |

| |

|

|

- Asset disposal |

| |

Asset Maintenance Management : |

| |

|

Following maintenance activities for assets can be managed and tracked using FOX-CAMMS |

| |

|

|

- Periodic planned maintenance audit (Periodic Preventive maintenance -PPM) |

| |

|

|

- Predictive maintenance |

| |

|

|

- Breakdown maintenance |

| |

|

Maintenance Works Order Management |

| |

|

Preventive Maintenance (PPM) Yearly / Monthly Scheduling and Daily Tracking of PPM |

| |

|

Break Down Maintenance History |

| |

|

Asset Predictive Maintenance (PM) |

| |

|

Alerts and Status notification |

| |

Asset Depreciation Calculation : |

| |

|

Provision to configure |

| |

|

|

- the company financial year |

| |

|

|

- the method of depreciation SLM |

| |

|

|

- start date of depreciation |

| |

|

|

- days to be considered for depreciation: actual number of days or same for all months |

| |

|

|

- write-off value |

| |

Inventory Management : |

| |

|

Provision to maintain maximum and minimum quantities of every material required to keep the plant or airport operational. |

| |

|

Tracking of inventory cost and records history of spares utilized, etc |

| |

Reports and Statistics : |

| |

|

|

- Budget report |

| |

|

|

- Procurement report |

| |

|

|

- AMC /Warranty expiry Report |

| |

|

|

- Machine Availability Report |

| |

|

|

- 80-20 parerto analysis of maintenance cost of various assets |

| |

|

|

- 80-20 parerto analysis of breakdown reasons for an asset |